Berm Monitoring System

SAFETY THROUGH THE MONITORING OF BERMS

Inferior berms that do not reach the required minimum height pose a high risk of accidents due to landsliding during work on slopes, if appropriate safety measures are not in place. In order to avoid fatal consequences, the berm is permanently monitored by the mobile Berm Monitoring System.

The BMS from Syperion is a software package and part of a complex safety system that helps to detect and fix substandard berms, dumps or dams in a fast, reliable and efficient way.

The monitoring system operates with the help of a RIEGL 3D laser scanner. Due to its long range of 400m or more it can be placed at a sufficient distance so that there is no additional danger from the system itself. The BMS is mobile and ready for operation within a few hours.

The BMS Software Package

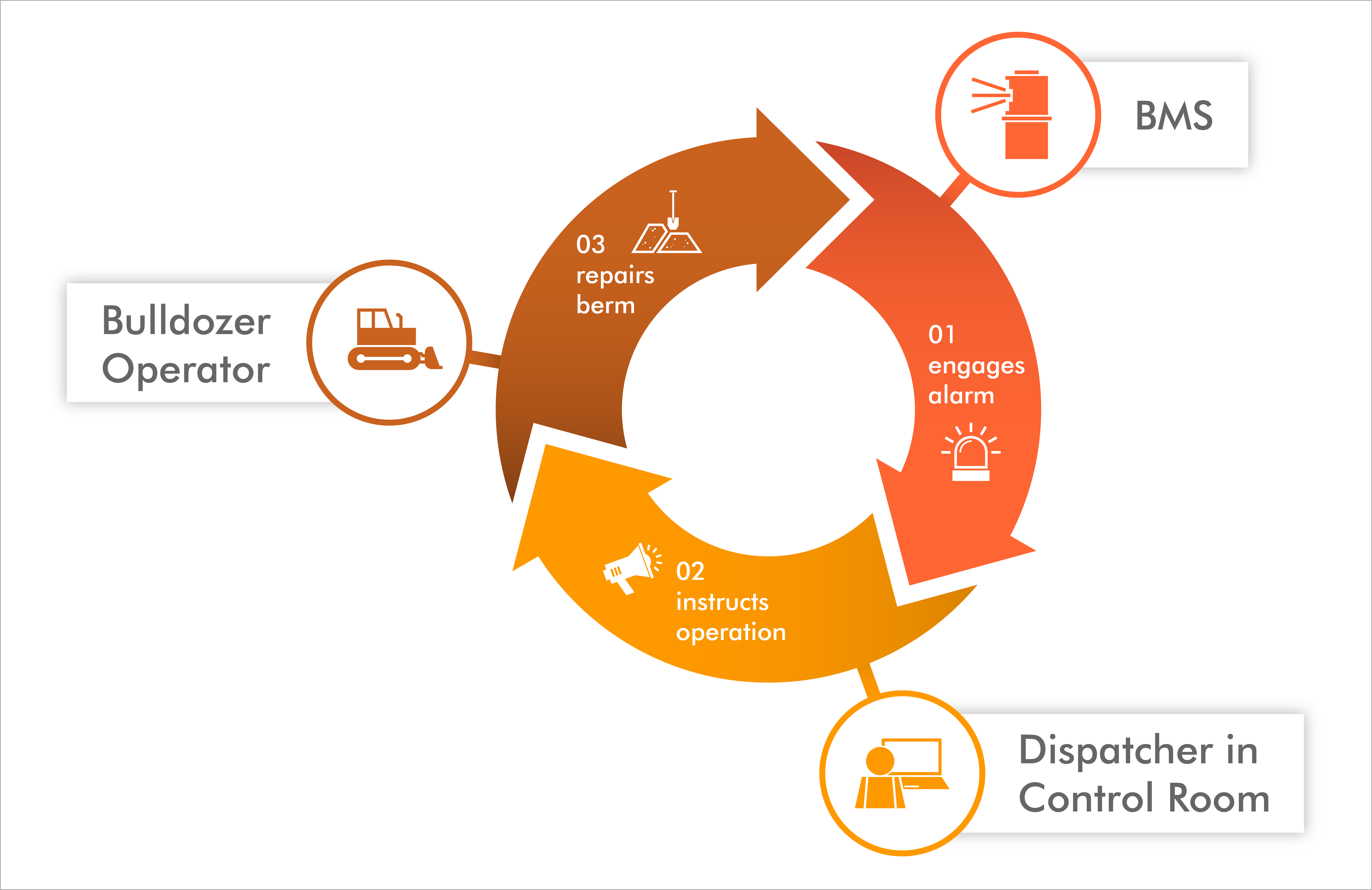

The PC-based BMS software package consists of a server software, running for example in a control room, and a trailer software, which runs directly on a mobile trailer in the vicinity of the areas to be monitored. In combination with the dispatcher in the control room and the bulldozer operator, the BMS is part of a closed control circle that prevents and if necessary, repairs substandard berms or dams.

The BMS Control Circuit

BMS CONTROL CIRCUIT

Together with the personnel in the control room and the dozer operator, the BMS forms a closed control circuit whose task is to prevent and, if necessary, repair defective berms.

01 ALARM

When detecting and identifying substandard berms, the BMS engages an alarm that is sent to the control center automatically.

02 INSTRUCTION

The responsible personnel in the control room sees the alarm on the BMS website and gives instructions so that appropriate repair measures can be initiated if necessary.

03 REPAIR

The bulldozer operator repairs the corresponding berm and reports the repair back to the BMS.

Contact

Please contact us and we will help you to develop an optimal solution for your application.

The Syperion Berm Monitoring System (BMS) provides information about current risks on waste dumps in order to prevent high potential hazards during open pit mining operations.

The Syperion Berm Monitoring System (BMS) provides information about current risks on waste dumps in order to prevent high potential hazards during open pit mining operations.